The fashion industry is facing a pressing challenge: an astonishing 60% of textile products are discarded before they ever reach a consumer’s wardrobe. This rampant waste isn’t just a missed economic opportunity—it’s a catastrophic environmental problem. The textile industry ranks as the second most environmentally damaging sector globally, primarily due to the use of toxic chemicals during dyeing, processing, and finishing. Now, more than ever, the industry must pivot toward sustainable practices that reduce waste and environmental harm.

A groundbreaking solution may lie in decolorizing and reusing textiles—particularly polyester, the dominant material in the global textile market. Enter a team of trailblazing researchers from the University of Fukui, Japan, who have optimized an innovative decolourization process that holds the potential to revolutionize the industry.

Breakthrough Innovation: Supercritical Fluid Dyeing

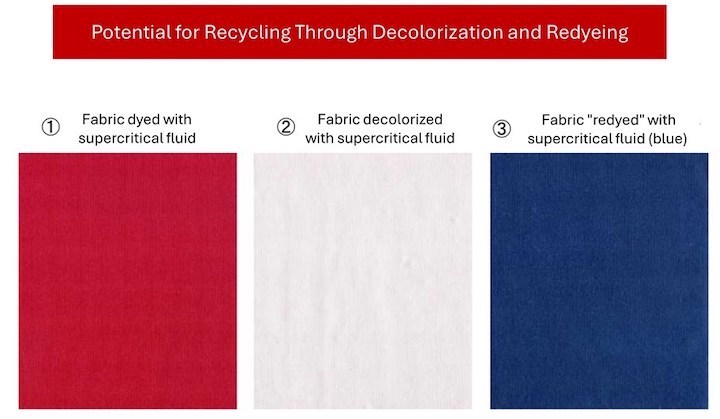

Led by Professors Kazumasa Hirogaki and Teruo Hori, the research team has perfected a process known as supercritical fluid dyeing. This cutting-edge method uses supercritical carbon dioxide (CO₂)—a state where CO₂ acts as both a gas and a liquid—to penetrate fabric fibres and extract dyes efficiently. The extracted dyes can be reused, and the fabric can be redyed, creating a sustainable cycle that minimizes environmental impact.

This research, which originated as part of the NEDO Feasibility Study Program and was further refined under the JST COI-NEXT Program for open innovation, has already yielded incredible results.

How It Works: The Science Behind Sustainable Decolorization

Using a specialized heated and pressurized vessel, the team created supercritical CO₂ fluid and mixed it with a carefully selected decolorizing agent. The magic lies in the agent’s solubility parameter, which falls perfectly between that of the dye and the fabric, enabling efficient dye removal.

The team developed three distinct methods for decolourization, each tailored to the properties of different textiles, dyes, and decolorizing agents:

Solvent Trapping Method

Supercritical CO₂ dissolves the dye, which is then trapped in a solvent phase at the bottom of the vessel.

Solid Trapping Method

A processing body is treated with a decolorizing agent or paired with an adsorbent inside the vessel. The supercritical CO₂ extracts the dye, which is then absorbed onto the processing body or adsorbent.

Homogeneous Method

The decolorizing agent is fully dissolved in the supercritical CO₂, enabling the extracted dye to also dissolve seamlessly into the supercritical fluid.

These methods achieved an astounding decolourization rate of over 90-100%, particularly excelling with polyester fabrics. Even more impressively, the processing liquids, extracted dyes, and decolorizing agents can all be repurposed, reinforcing the process’s sustainability credentials.

Toward a Circular Fashion Economy

This innovation isn’t just a scientific breakthrough—it’s a rallying cry to reimagine the textile industry. By transitioning from a wasteful “make, use, and dispose” model to a sustainable “make, use, and reuse” approach, this technology could catalyze a seismic shift toward a circular economy in fashion.

The University of Fukui research team is now actively pursuing the commercialization of this technology. Their vision? To create a world where sustainability is the standard, not the exception, and where discarded textiles become valuable resources rather than environmental liabilities.

The Future of Fashion is Here

This pioneering work represents a major step forward in addressing the environmental toll of the fashion industry. As this technology gains traction, it has the potential to transform how the world views textiles—not as disposable items, but as renewable assets in a sustainable, circular economy.

It’s not just about making clothes anymore; it’s about redefining what the industry can achieve when innovation and sustainability align. Fashion’s future looks brighter—and greener than ever.

Research project name: NEDO Feasibility Study Program / Feasibility Study Program on New Technology. JST COI-NEXT Program on open innovation platforms for industry-academia co-creation (COI-NEXT).

Researchers name: Professor Kazumasa Hirogaki, Visiting Professor and President of SUSTAINA TECH Co., Ltd. Teruo Hori.

Affiliation: University of Fukui