Every year roughly one-third of all food produced for human consumption gets wasted or lost. Instead of taking it just as a sad reality today’s entrepreneurs started to look at the food waste as a new opportunity bringing a sustainable solution to replace the settled materials. The Apple Girl is a biotechnology company located in Copenhagen, Denmark supplying creators who are excited about the innovative future with a safe, biodegradable and high-performance material. The concept of using apples for making a vegan leather led the company to gain Scandinavian acclaim and several awards already. Started in 2016 The Apple Girl doesn’t tend to stop, “I have been up to my elbows in apple ever since – trying to make something from this waste and utterly inspired in the process,” says Hannah Michaud and shares her vision of a sustainable future.

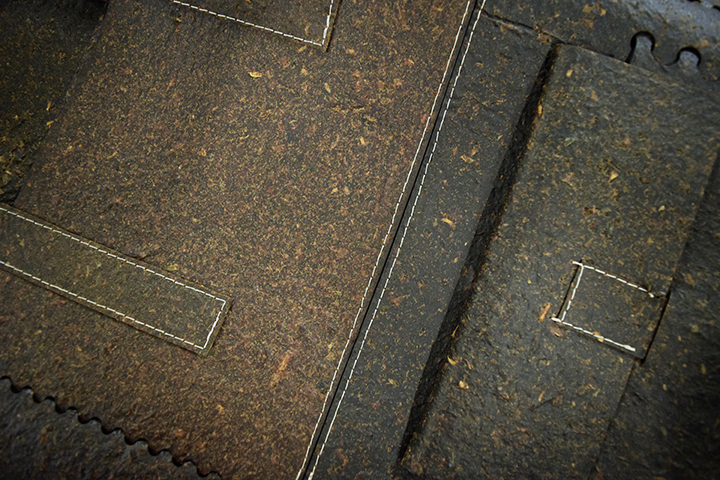

The future of materials is in food waste. We’re a team of creative, rebellious geeks in love with changing the world – today, here and now! This purpose and sense that we have is not only the opportunity but the responsibility to make a difference in the world with this luscious, beautiful red goodness. Apple pulp, sitting in copious amounts all over the globe, wants to become something! Something better! Something useful! A durable, high-performance leather from food waste that can be used across industries, in any context where animal leather is used now and even more.

We’ve come a long way since our first test run. This sense of purpose me and my team have, this opportunity to really solve the leather problem, gets us up in the morning and it’s why we want to spend all our time doing this! We are the team to make the first 100% biodegradable vegan leather made from food waste. I’m a Material Designer with a background in fashion. Mark leads our Technical team with a PhD in Chemistry. In the lab we are a well-oiled machine, thinking outside the box, yet logical and analytical. Mikael leads business development with a background in Sustainability. He has years of experience running a family business in Germany and is an expert in customer acquisition. Today we have a more highly evolved, better and finer recipe, but still, have a lot to learn about what this material can do. In scalable production, we’ll work to supply the same quality every time and ensure cost efficiency. We aim to have a technology mature for patenting in two years. I guess our activity says more than we do – The Apple Girl is super passionate about using food waste in really out of the box and meaningful ways.

The article was originally published in ‘SwO street’ No. 30 (www.swo.lt/swo-street-nr-30).